October 2022

How 'Green' is our Activated Carbon?

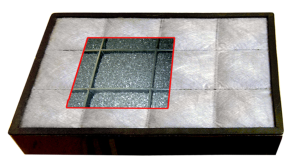

Here at Safelab we produce activated carbon filters for our own Safelab ductless fume cupboards, along with filters for many other makes and models of fume cupboards.

We manufacture our carbon filters on site, which allows us full process control and traceability. But where do we get our carbon from, and in a world where becoming carbon neutral (or even negative) is the phrase on everyone lips, how can this be sustainable?

What is activated carbon?

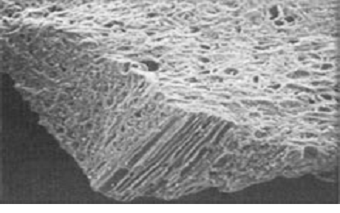

Activated carbon is a form of carbon that is extremely porous. It can be manufactured from a variety of carbonaceous raw materials including coconut shell, coal, peat or wood. The choice of raw material influences the characteristics and performance of the activated carbon, allowing it to be used across a wide range of applications.

The carbon is activated by treating the raw material with steam or chemicals, resulting in a pore structure with an extensive internal surface area. Activated carbon can have a surface area of greater than 1000m² per gram, meaning 3g of activated carbon would have the surface area of a football field.

Our activated carbon is often additionally chemically impregnated to optimise it for the adsorption of a specific range of compounds including acids, ammonia and amines, formaldehyde and mercury-based products.

Where does our activated carbon come from?

At Safelab, we use coconut shell activated carbon. The microporous structure results in an extremely large surface area, promoting adsorption of airborne contaminants at high capacity.

Coconut shell activated carbon is often the most environmentally-friendly option, and as long as coconut plantations are managed in a sustainable manner the resource is fully renewable.

We source our activated carbon from a company in Bristol called Eurocarb, the European subsidiary of Haycarb who are the leading manufacturer of coconut based activated carbon and one of the largest carbon manufacturers globally.

Haycarb prioritise social, economic and environmental responsibility, and all stages of the production of the activated carbon are geared towards keeping the carbon footprint as low as possible.

The sustainable process

The activated carbon that we use in our filters comes from production plantations located in Sri Lanka, Thailand and Indonesia. The advantage to using coconut shells as a raw material versus traditional coal, aside from the performance benefits, is that coconut shells are a renewable resource and palms trees can be replanted to ensure the supply does not run out.

The process the coconut shells go through to produce the activated carbon is pollution-free and carbon neutral. During the production process a significant quantity of waste heat and gasses are released, these are then used to generate all of the steam and the majority of the electricity required to run the production process, in effect it has gone round in a circle. Any excess waste gas is used to produce electricity and is sent back to the national grid.

Traditional methods of activated carbon production produce large amounts of both charcoal and carbon dust, which are then released into the environment and cause significant pollution. Haycarb captures and re-uses the dust produced from the coconut shells to produce different grades of carbon for processes that require much smaller particles, ensuring minimal waste and maximum efficiency.

Water use

Despite coconut shells being a reusable resource, large quantities of water are required to ensure that the palm trees can grow. Sri Lanka in particular has suffered from freshwater scarcity recently due to over-development, natural environmental disasters such as floods and tsunamis, and worsening droughts due to climate change.

Whilst the water used to supply the coconut trees can be waste water, which is abundant across the region, water required for people and livestock needs to be clean and safe to drink. Haycarb has developed a specific range of activated carbon that can be used to purify water, and this has been rolled out across Sri Lanka to assist with the water crisis.

In fact, over 70% of the activated carbon Haycarb produces is used to purify air and water globally, assisting with many environmental projects both in scientific and governmental settings.

Your filter selection

Given details of your intended application we can use our in-house knowledge and experience to recommend the most suitable activated carbon for your use.

We can also provide HEPA filters, separately or as combined units with our activated carbon filters. Please contact us with your filter requirements and we will be pleased to help.

Read more about Haycarb and their activated carbon here.